INDUSTRIAL STRUCTURES

Bunkers

In a Coal Mining Organization, the distressed Ground Level bunkers were strengthened by encasement with high grade micro-concrete and protective coating was applied to entire concrete area to increase durability of the structure.

Pre-Heater Buildings

In a Cement Factory, the distressed structural members of the pre-heater building were strengthened by concrete encasement and the honeycombed areas were treated using epoxy injection grouting.

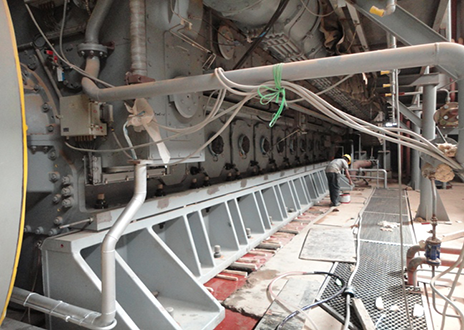

Machine Foundations

In IRAQ, to stabilize the base for a heavy machine, grouting with high grade, non-shrink cementitious material was carried out at the base of the machine.

Innovative method of stabilizing rocks by Post Tensioning

At Durga Malleswari temple, Vijayawada, Andhra Pradesh it was proposed to widen the road on to the hill by excavating part of the hill, which would enable to ease the congestion especially during the peak festival season.

This required blasting the rock to widen the road. In the process of uncontrolled blasting, the rocks become very unstable. At that stage it was very difficult to stabilize the rocks by the proposed conventional method of rock bolting,as it was not only very difficult to access the rocks at a height of 60 m but also scaffolding could not be erected to such heights. Further, there was a great risk of the rocks destabilizing further during the drilling process.

M/s Varshitha was called in to suggest a suitable method to address the practical difficulties and also suggest and execute a suitable system to stabilize the rocks that too in a very short available period of 20 days before the festival season.

Innovative technique of Post Tensioning method was adopted and executed successfully. The process involved the following steps

Drilling pair of holes at a spacing of 1.0 m c/c in stable rocks both top and bottom with a spacing of 300 mm between each hole in the pair.

Fixing 3 m long HT strands in the drilled hole using polyester resin grout.

Fixing anchor blocks both top and bottom to each pair of HT strands

Connecting the corresponding anchor blocks at top and bottom with HT strand (HDPE pipe covered and coated with anti corrosive coating). Locking the same with barrel and wedge system.

The strands were stressed to approximately 4.0 tons each and thus effectively pressing down the rocks and locking the same.

Chain link mesh was spread over the strands securely tied to the strands and anchors. Chain link mesh is mainly to stop any smaller pieces of rock rolling down.

The complete job was carried out in less than 90 days well before the rush season of the temple and the total stretch completed is 420 m